Turbocharger Maintenance 101

Turbocharger Maintenance 101

Welcome to turbocharger maintenance 101, here we will provide the answers to all of your basic turbocharger questions and also give you some helpful tips for prolonging the life of your turbocharged vehicle. To get us started, we are going to keep this section very simple and target the main causes of maintenance related turbocharger failures. Our first topic is going to be the three most important things you can do for your turbocharger: engine starting, engine shut off and engine oil service .

The first thing that causes rapid wear and stress to a turbocharger is simply starting the cars engine and driving off. Today's car is a very sophisticated machine that is very easy to operate, just turn the key, drop it into gear and you are on your way. There are hundreds of things that happen in a matter of seconds from the time you start the car, and one of the most important is the flow of oil coming from the oil pump to the turbocharger. When your engine is first started, there is a very slight delay until the oil being pumped from the engine's oil pan reaches the turbocharger. In that amount of time, the turbocharger is already spinning many times faster than the engine. We know that the oil is the only lubricant for the turbo, so it is very important that it is being delivered quickly and efficiently to keep from damaging the bearings in the turbocharger. In this critical time, it is best to allow the car to idle for at least 3-5 minutes before driving off for the first time that day. Afterwards, if the car is left sitting for less than 3 hours it is OK to reduce this idle time down to around a minute. The reason we want to do this is very simple, oil temperature. When the oil temperature is cold from the engine not operating over some time, it is thick and slow to flow through all of the oil passages, lines and filters found in the oiling system. Slow moving cold oil cannot get into all of the passages and clerances found in a turbocharger, and because the turbo rotates at a very high speed the damage caused by the lack of oil flow happens very quickly. The ideal temperature for oil to flow and provide proper lubrication is between 180-210° F, and on a cold day it can take an engine up to 20 minutes to reach this oil temperature. Once you have let your car warm up for a few minutes, it is best to drive your car easy for at least the next 5 minutes, avoiding giving the car more than 1/4 throttle. This will give the oil time to properly warm up and do its job of lubricating all the vital areas of your turbocharger.

There has been many topics discussed around how long to let a turbocharged car idle before shutting off the engine. First we will tell you why your car needs to cool down before turning off the key and also why it is not good to allow a car to idle for a longer period than needed for proper turbocharger life. We know that a turbocharger operates at a very high rotational speed and it is fed lubricating oil from the engine, so it only makes sense you want to slow down the turbo's speed and also provide it with oil before shutting the car down. Once you turn off the engine in your car, the turbocharger will continue to spin for up to a minute or more and during this time oil is not being delivered to the turbochargers bearings, causing wear. To help prevent this from happening, we have been told in the past to let the engine idle for a few minutes prior to turning off the key. The good thing that happens during this time is in fact the turbo will slow down, but if allowed to idle for to long the temperature of the engine compartment, engine oil and the turbocharger will start to increase. The reason for this is today's car is designed to be moving while it is operated, allowing air to pass through the radiator and engine compartment, keeping it cool. The best thing is to drive your car as easy as possible when you are getting close to your destination. Once you are safely in your parking spot, allow the car to idle for no more than 2 minutes. This time will be adequate for both the turbochargers speed to slow, and for the temperature not to increase in the engine compartment.

Since the engine's oil is also the lubricant for the turbocharger, keeping up with the oil change intervals and using the correct oil type is very important. Most consumers turn to the vehicle's service guide for this information but there are a few problems with this information.

Turbocharger Maintenance 102

Welcome to the next level of turbocharger knowledge. In turbo maintenance 102 you will find information on various aspects of the turbocharger itself. This is geared to help out the DIY enthusiast who likes to service their own vehicle.

The first simple topic to cover is changing your own air filter. Over the past 13 years the amount of turbocharger problems arising from the ingestion of small foreign objects is only surpassed by damages from oil and oiling issues. Many people take for granted how simple most air filter assemblies are to service. Usually it takes less than 30 minutes to open up the air filter enclosure, remove the old filter and install the new one. The problem usually arises when something as simple as a stray piece of pine straw or other debris enters the air filter housing un-noticed. Since we know the compressor wheel of the turbocharger is made from aluminum, and spins at a very high speed that it is very susceptible to damage from something coming in direct contact with it while it is spinning. Before removing any of the air filter housing to gain access to the filter, take the time to clean and inspect the area around the housing. Once you have the old filter out, use a flashlight to inspect the inside of the housing as well as any ducting leading to the turbocharger. Small particulates can damage the turbocharger quickly, so be very thorough in your inspection process. Before installing your new filter assembly, it is also advisable to take the time to inspect the filter for any flaws in the media or the gasket sealing surface around the perimeter of the filter. Remember, the cleaner the better.

We have covered the importance of engine oil quality, now let us cover changing the oil itself. You will go through the normal draining procedure, and removal of the oil filter assembly. Prior to installing your new oil filter, here are a few tips to help keep any potential debris from entering your engine by mistake. First, take a clean lint free rag and wipe the filter mounting boss on the engine, taking note to observe for any signs of old oil filter gasket or any loose debris that might be present on the filter mounting boss. Second using your cloth, wipe out the threads in the center of the oil filter mounting flange. I owe this to my friend Matt, he pointed out many times the threads would still contain small metal particles as well as cutting grease left over from the manufacturing process that need to be removed. Also use a flashlight to look down into the filter, making sure it is in fact clean with no debris from the packaging left inside. Always fill the oil filter with a small amount of oil prior to installation, this will help the oil pump to prime faster before starting. At the same time you fill the oil filter, take some extra oil and lubricate the filter o-ring to keep it from binding or sticking on installation. After the oil is filled to the correct level in the crank case, find the main fuel pump relay and unplug it or its fuse. Proceed to spin the engine over with the ignition switch for 5 seconds, observing the oil pressure gauge or light. If the gauge does not register pressure within 5 seconds of cranking the engine, repeat after allowing the starter to rest for 30 seconds. Once your engine registers oil pressure, reconnect the fuel pump relay/fuse and start the vehicle and check for leaks. Priming the oil system will provide the turbocharger with oil pressure faster when the engine is started, prolonging the life of the turbo bearings.

Next on the service list will be your spark plugs. Many of today’s engines have the spark plugs located in a recess down in the cylinder head. Take the time to check for dirt and debris around the spark plugs before removing them, this will ensure that no foreign objects will enter the engine when the spark plugs are removed. Anything that is missed becomes a risk to damage the turbine wheel in the turbocharger when it is expelled from the cylinder on start up. Always make sure you use the correct spark plug recommended by your vehicle manufacturer to prevent damage due to pre-ignition or mechanical damage.

Fuel filters need to be changed every 10,000 miles on any performance turbocharged vehicle. Make sure to use the correct OEM fuel filter for your car to prevent fuel starvation due to a restrictive filter. Turbocharged engines operate at a very specific air/fuel ratio, any restriction presented from a clogged fuel filter or one of inadequate specification can cause serious engine and turbocharger damage quickly. A free flowing fuel filter also prolongs the life of the fuel pump by removing restriction the pump must overcome to deliver fuel to the engine.

Turbocharger Maintenance 103

This section will cover more in depth preventative maintenance, starting with one of the most overlooked parts of a turbocharger installation, the high pressure hose couplers that connect the turbocharger to the intercooler and finally the engine. Most of today’s turbo systems operate at pressures over 12 psi, so even the slightest problem with a coupler can create a leak of boost pressure. Turbochargers already operate at a high revolution speed, and any air leak after the compressor will cause the turbocharger to work even harder to overcome the pressure loss. Remember that the wastegate actuator on most turbochargers regulates the amount of exhaust energy present at the turbine wheel required to produce the shaft speed necessary to turn the compressor wheel fast enough to create boost pressure. The turbochargers wastegate is blind to the fact there could be a pressure leak, so it is going to try and force the turbo to over come this leak until the desired positive manifold pressure is obtained. This of course will create a turbocharger over speed condition, cutting the life of the turbocharger drastically.

To get started, first do a visual inspection of all the hoses, clamps and tubes. Look for signs of a pressure leak, such as damp or oily residue around the hose or clamp, bulges or soft spots in the hose, rubbing against another object that could cause abrasions or tears and finally inspect the intercooler core if equipped for indications of impact from gravel or other objects thrown up from the road. Repairs can be as simple as tightening or repositioning a hose or clamp, to replacing torn or damaged couplers.

If your car has over 100,000 miles on the odometer, it is advisable to remove the intercooler and piping, thoroughly cleaning the entire system to remove oil residue and check for any problems. If you have the equipment, pressure testing the intercooler system by making a pressure plug for the front of the turbocharger and applying pressure to the system while it is installed on the car will provide the ultimate way of knowing your system is sealed and functioning properly.

The next item of inspection for the high mileage car will be the oil supply line. Over time this line is subjected to oil flow and of course temperature extremes. The oil will start to turn to carbon in the areas of high heat, and if left un treated can create a detrimental restriction of oil flow to the turbocharger itself. Usually oil supply lines are relatively inexpensive from the dealership, and if your car has over 100,000 miles showing, the line needs to be serviced. Note that this line cannot be reliably cleaned, replacement is the only safe way to complete this job.

While you are servicing the high pressure oil feed line, take the time to inspect all of the oil return line gaskets and connections. Although it is a very important line, cleaning and re-installing is often the only maintenance needed, there is no need to replace the line with a new one unless it is damaged beyond service. The same will also hold true for the turbocharger coolant lines, if equipped.

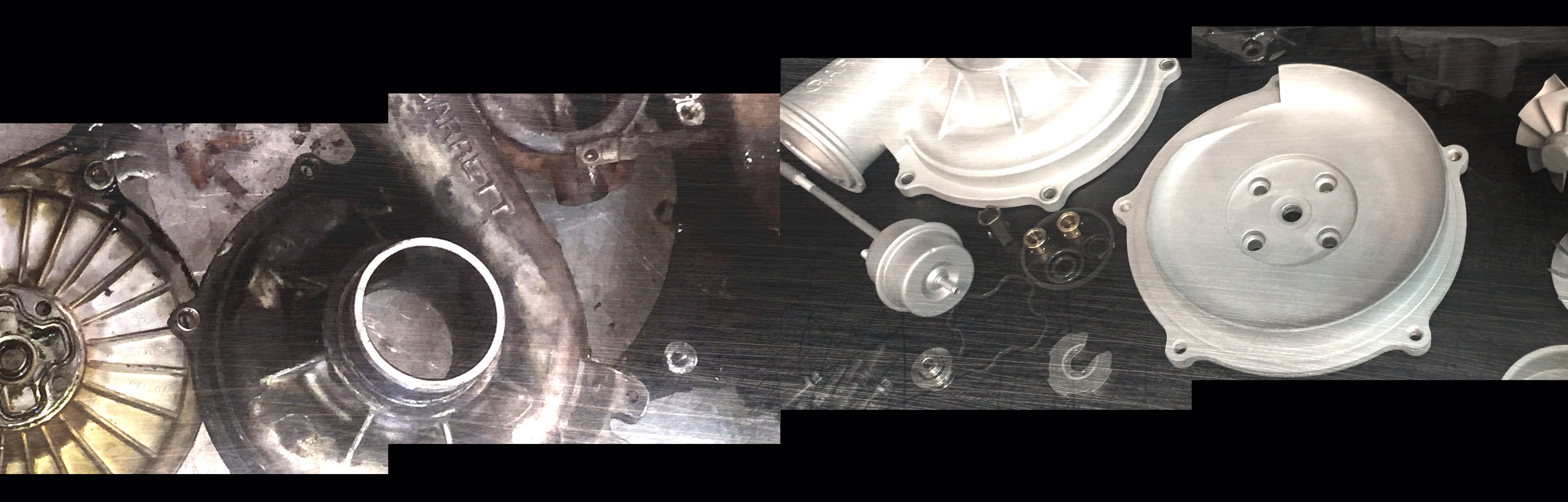

One question we get asked a lot is how to do a visual inspection of the turbocharger itself. First off, you will need to gain access to the turbochargers compressor inlet. Once you can see the compressor wheel through the inlet opening, observe the area for an excessive amount of oil present in the inlet, or on the compressor wheel itself. The wheel should be a natural aluminum color, with no signs of impact damage or contact with the compressor housing. If it is possible to spin the turbocharger with your fingers, note any resistance or noises. The turbocharger should spin freely, with no rubbing, scraping or other unusual sounds. The turbocharger will have small amounts of radial (side to side) movement in the bearings, but it should never be able to make contact with the compressor housing inlet. Your turbo should have no noticeable axial (in and out) motion that you can feel. If any of these diagnosis fail to pass inspection, the turbocharger needs to be serviced immediately.

Turbocharger Maintenance 104

This is a general guide to tricks for removing your turbocharger from the vehicle. I will not go into specific vehicle instructions but just hit the high points of the removal to help with the task. If you are removing your turbocharger to send in for service, please only remove what is needed to get it off the vehicle. Items such as the wastegate actuator, exhaust elbow, O2 sensor and coolant lines can be left on the turbocharger, we will be happy to remove, clean and re-install these at the time of turbocharger rebuild.

Be sure to cover any intercooler, air filter or other openings that are going to stay installed on the car with tape to keep anything from contaminating the system!

First off, start with a cool engine and follow all the steps found in the OEM service book. One trick I have learned is how to remove a stubborn bolt out of the exhaust side connections on the turbocharger. Before you attempt any type of loosening, get yourself a small hammer and a flat nosed punch. Over time the hardware will rust and corrode between the threads of the fastener and the manifold or housing. Giving each one of these bolts a liberal shock with the hammer and punch will help loosen this corrosion, allowing the fastener to loosen easily. Once you have shocked the hardware, use a good penetrating oil such as PB Blaster, Kroil or your favorite and give the bolts a good dose. Allow the oil to do its job for at least 20 minutes, and do not be afraid to work the hardware a little at a time, turning it in a alternating rotation while spraying the lube from time to time. Avoiding broken bolts and stripped threads is your goal.

If you are installing your turbocharger on a new engine, please be sure to place emphasis on determining if the oil filter system on your engine filters the oil before it reaches the turbocharger, oil contamination from a new engine’s break in will quickly destroy the bearings of your new turbocharger. Installing a pre filter in the oil supply line, along with a strong magnet placed on the oil filter body will ensure a clean supply of oil reaches the new turbocharger.

We will be continually adding to this section, if there is something you would like to see covered, please contact us with your request!

-Turbo Repair