Turbocharger Part Definitions

Here is a list of common parts with explanations of their function along with photos. This will help you gain a solid idea of common parts and terms used in the world of turbochargers.

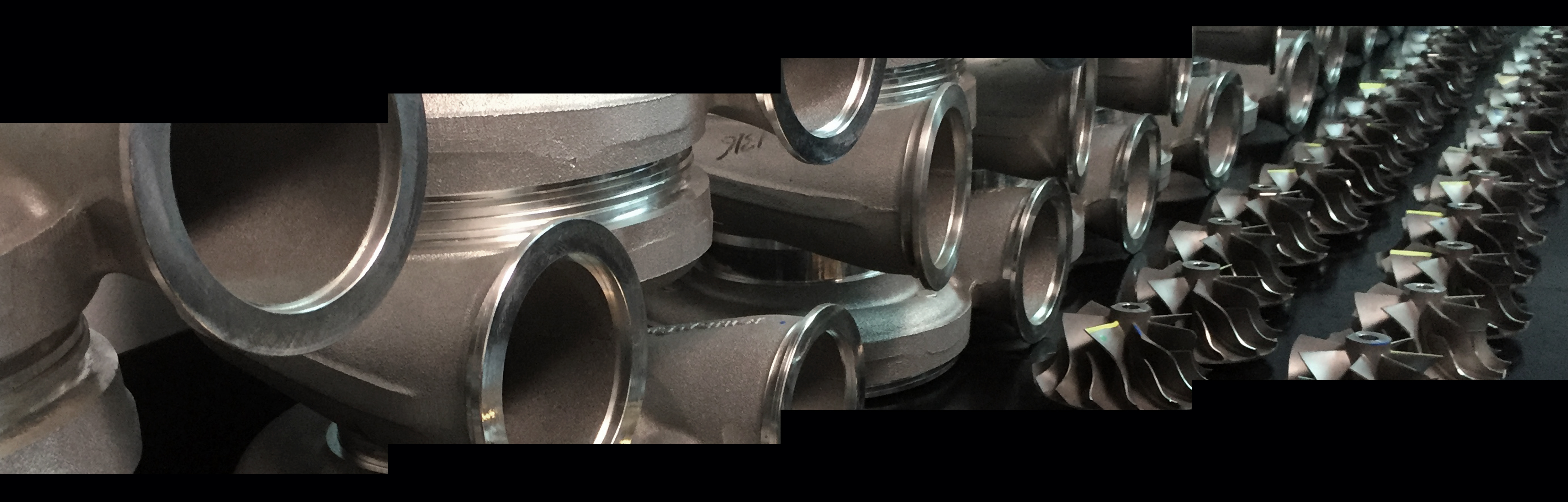

Compressor Housing

This is usually an aluminum housing that contains the volute that will channel the air from the air filter assembly to the compressor wheel and finally out to the intercooler plumbing. It's design and function are fundamental to the centrifugal compressor family, usually the housing will have a volute or scroll design that is used to promote air flow and pressure for the engine.

Shaft Nut

Retains the compressor wheel and thrust collar to the turbine shaft

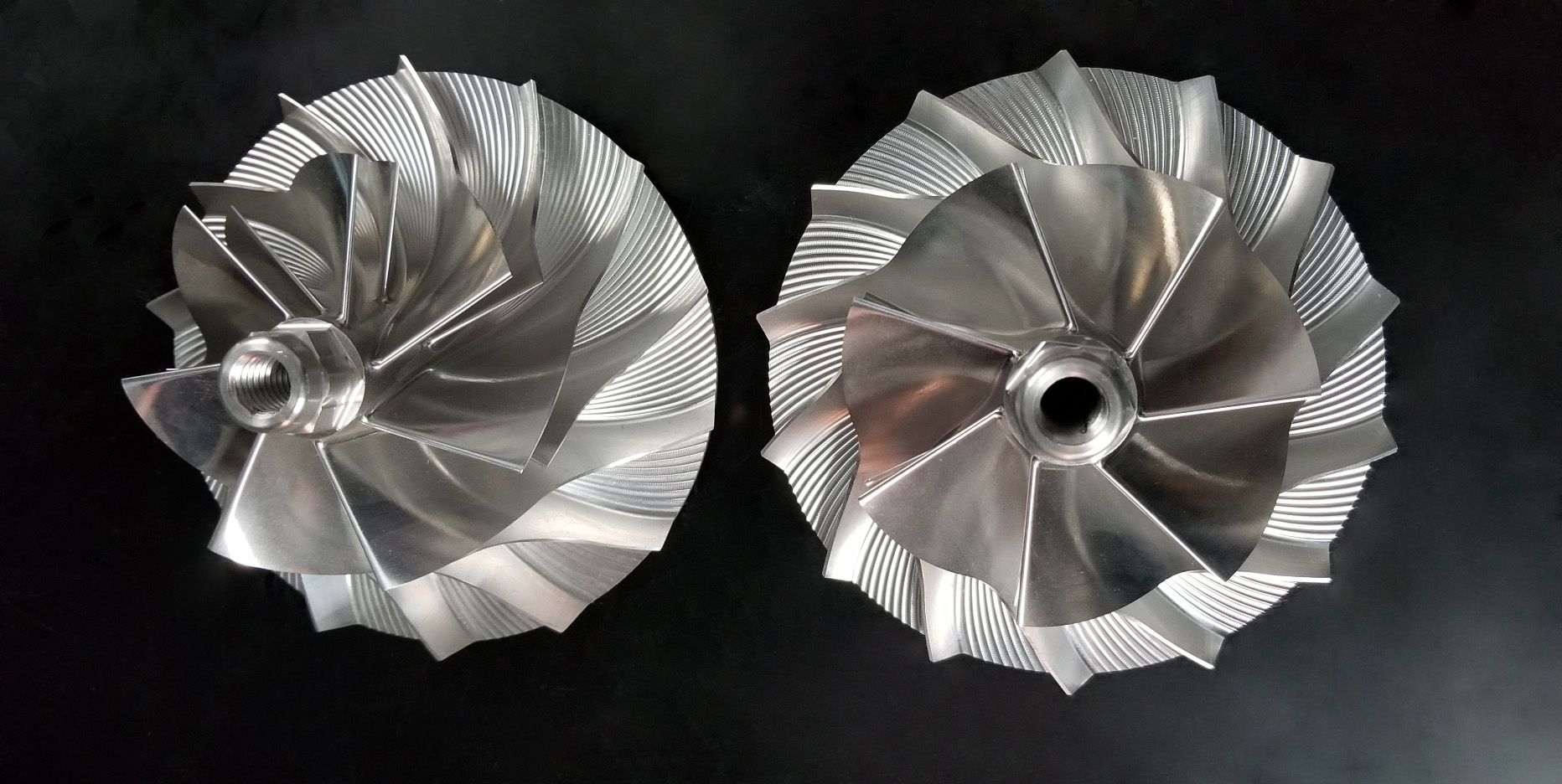

Compressor Wheel

The compressor wheel is located in the compressor housing. It is usually made of aluminum, either cast or forged milled billet. The compressor wheel pulls air from the air filter assembly and then centrifuges it at a high rate of speed into the compressor housing volute to produce pressure to feed the engine. Compressor wheels are often measured in the exducer or major dimension, with the inducer being called the compressor wheel trim.

Back Plate, or Seal Plate

This connects the bearing housing to the compressor housing and serves many purposes. Besides being a method of attachment, this plate usually provides the sealing surface for the compressor side seal. It is also the diffuser for the compressor wheel exducer to compressor housing volute, and also the retaining device for the thrust bearing system.

Compressor Piston Ring

The compressor side piston ring is a circular spring steel ring that is used to provide a dynamic seal between the back plate and thrust collar. This seal relies on the design of the thrust collar and proper clearances to provide both oil control as well as keeping contaminates from entering the bearing system from the compressor side of the turbocharger.

Star Spring

Used to retain the thrust bearing in some turbocharger designs

Quad Ring

A simple sealing ring located between the back plate and bearing housing

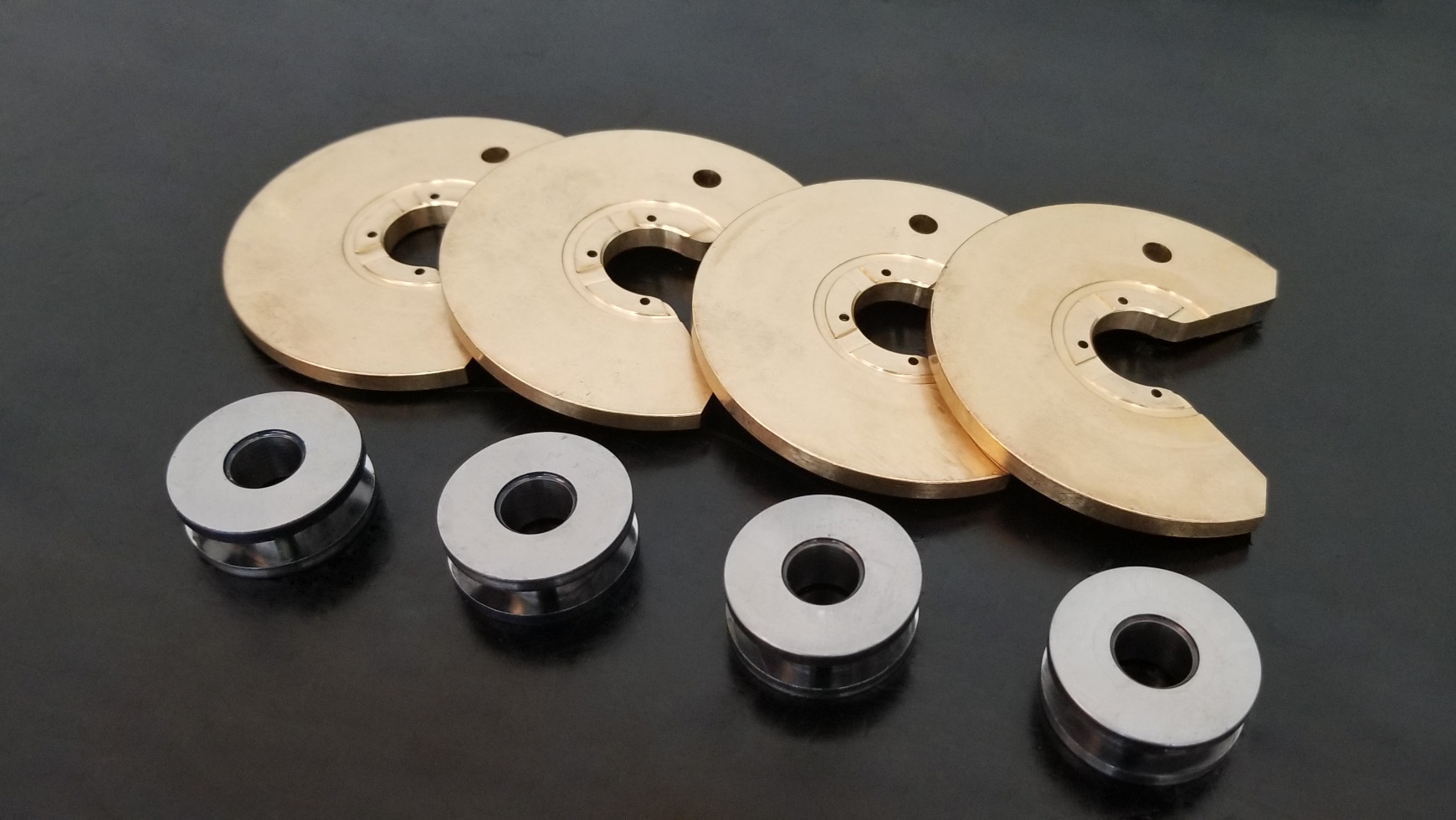

Thrust Bearing

The thrust bearing in a turbocharger is the main locating structure for axial movement. Axial, or “in and out” movement must be held in tight tolerance to maintain the exact clearance needed between the compressor and turbine wheel to housing relationship. Thrust bearings can be made of bronze alloy, sintered iron or steel alloys depending on application. All thrust bearing designs utilize hydro-dynamic action with oil as the medium to eliminate friction and allow precision location at high speeds.

Thrust Collar

The job of the thrust collar is to provide a locating surface between the sides of the thrust bearing. The thrust collar also provides the compressor side seal ring or carbon seal a location point. The collar fits around the thrust bearing usually within .0025” of nominal clearance.

Bearing Clip

Locates the journal bearings in their proper location within the bearing housing

Journal Bearing

Bronze bushing used to locate the turbine shaft radially within the bearing housing. These are usually full floating hydro dynamic bearings that rely on oil film to provide operation at high speeds.

Bearing Housing

Usually cast iron, the bearing housing locates the bearings, provides the oiling circuits for the thrust and journal bearings and in some cases has water cooling passages to aid in the cooling of the turbocharger.

Heat Shield

Protects the back of the bearing housing as well as the turbine side piton ring seal from direct heat generated by the flow of exhaust through the exhaust housing.

Turbine Piston Ring

The turbine piston ring is a circular spring steel alloy that is used to provide a dynamic seal between the turbine wheel and bearing housing. This seal relies on the turbine wheel design to keep oil away from the turbine housing as well as exhaust gases from entering the bearing housing assembly.

Turbine Wheel

The turbine wheel and shaft assembly transfers the exhaust energy radially to the compressor wheel. Turbine wheels are usually made of Inconel or other high temperature alloys to allow them to perform in a temperature environment that regularly exceeds 1500˚F. The turbine wheel also holds the turbine side piston ring, provides the bearing surface for the journal bearings to ride and also has the quill that holds the thrust collar, compressor wheel and shaft nut. Turbine wheels are usually measured by inducer dimension in millimeters and exducer dimension in trim.

Turbine Housing

The job of the turbine housing is to collect the exhaust gases and direct them through a volute to the turbine wheel inducer. This increases the velocity of the exhaust gas and provides the drive energy for the turbine wheels rotation. The turbine housing will usually be made of cast iron, or other high temperature alloys. Some turbine housings will have the wastegate valve built in to the housing.

Wastegate Actuator

The wastegate actuator uses a diaphragm and spring to hold tension on the wastegate valve assembly. The spring is calibrated to a specific pressure, and once that pressure is achieved at the intake manifold it is channeled into the actuator body through a port connection. This pressure moves the actuator rod, opening the wastegate valve and regulating boost pressure.

Rotating Assembly

Most standard turbocharger designs have a rotating assembly that consists of the turbine wheel, thurst collar assembly, compressor wheel, and shaft nut. It is important if any one part of this assembly is changed, that the unit as a whole be rechecked for proper balance.

For general information about WORK Turbochargers policies, guidelines, warranty, shipping, and order information please see Turbo Repair FAQ

If you have any suggestions for this FAQ or questions that require more information please contact us!